What does it mean for preconditioning electric vehicles?

If you’re working in public transport in Europe, you’ve probably heard about the VDV 261 standard. You might also be familiar with the need to precondition electric vehicles (EVs) before they go into operation. So what is VDV 261 exactly, and how does it work? What issues does it solve? In this post, we explore these questions and more.

What is VDV 261?

VDV 261 is a data communication standard between charging stations and vehicles that allows the preconditioning of electric buses via the software in charging stations. In simple terms, it helps operators preheat or cool down their eBuses before they leave the depot. This means that not only will the inside temperature be comfortable for drivers and passengers from the beginning of service, but the bus will also start its route with the most range possible. Plus, it offers a software-driven approach, meaning operators don’t need to send out their employees to manually start the preconditioning of each bus—it can all be scheduled and done automatically.

What does VDV 261 mean for public transport operators?

VDV 261 meets a major need of operators who are running electric buses by providing a standardized approach for preconditioning electric bus fleets. It allows operators to have their eBuses preheated in colder weather or cooled down on warm summer days before the vehicles actually leave the depot. In some countries, it is also required by law and requested by work councils that buses leave for service with a specific inside temperature range for drivers and passengers.

In short, with VDV 261 incorporated into overnight charging, operators can ensure that their vehicles leave the depots with the necessary, comfortable interior temperature, while the vehicle batteries are not depleted and have sufficient state of charge (SOC) to run their route.

How does VDV 261 manage the preconditioning of electric buses?

VDV 261 builds on other communication protocols, like ISO 15118 and OCPP. VDV 261 makes use of the existing charging infrastructure and communication protocols to allow preconditioning. It’s exciting to see how industry standards continue to build on and inform one another, accelerating progress.

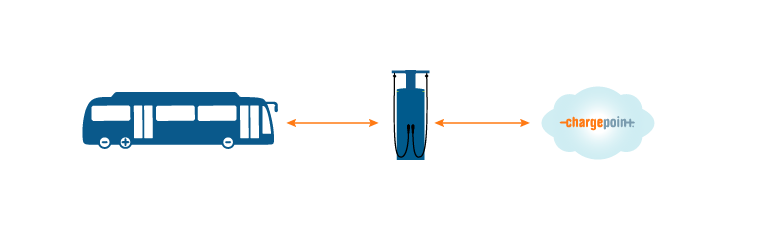

To charge in the depot, any eBus needs to be connected to a charging station. The associated telematics platform sees and recognizes the bus, and the following information is sent to the vehicle:

- the departure time, or the time when the vehicle must be done preconditioning;

- the type of preconditioning that must happen (e.g.,cooling, heating or ventilation);

- the outside temperature, in case the bus is in the hall and the outside temperature differs a lot from the indoor one.

Given these parameters, the vehicle knows whether it needs to be preconditioned, what exactly it should do (heat or cool) and when it must be ready (departure time). Based on this information, the vehicle can use its climate systems to prepare to drive off at the perfect temperature.

The eBus and charging station communicate using the charger as a proxy. They communicate several times overnight, to make sure the software systems are up-to-date with the latest information, and to make sure the bus is preconditioned at the start of its service.

During this process, the electric bus is constantly connected to the charging station. While preconditioning, the vehicle charges so that it compensates for the energy used for temperature control. When the desired temperature is reached, the bus stops preconditioning and is ready to start its day.

What are the main advantages that VDV 261 gives public transport stakeholders?

As public transport has been electrifying more and more, operators have noticed some differences in managing electric buses. For example, if you heat up electric vehicles while not charging, you will lose range. Heating up a bus from an outside temperature of -10°C during winter to a comfortable 15-18°C inside the bus will use a lot of energy before the bus has even left the depot. This negatively affects the range. In the worst-case scenario, the bus might not make its full route and might need to be towed away. VDV 261 helps operators to optimize their process and planning and reduce risks. Furthermore, the standard reduces range anxiety and increases passenger and driver comfort, while ensuring planning accuracy and reliability.

What are the requirements for preconditioning?

For successful preconditioning, both the charging station software and vehicles must be VDV 261 compliant.

I like to refer to the standards as a language, and to the chargers and vehicles as people. They might speak the same language but with different regional accents, which can lead to misunderstandings unless you practice.

We have the same situation with VDV 261. All parties might read the standard but might also interpret it slightly differently. Therefore, it’s always necessary to test the communication between bus, charging station, and software to ensure that they exchange the right information so that the buses start their routes preconditioned, with the right inside temperature.

To get the most value out of VDV 261, we also recommend that operators be VDV 463 compliant. This additional VDV standard (which we talked about in another article) defines the interoperability between the charging station software and depot management systems. VDV 463 compliance will help to fully automate the process of preconditioning. The charging station will communicate to the depot management systems, exchanging relevant information to ensure a smooth process of getting vehicles ready for their routes. For operators who don’t already have a depot management system, we can also work on an alternative way to get the necessary information for a successful preconditioning process.

Standards such as VDV 261 are crucial to the success of fleet electrification. We’re proud to be able to work on defining, implementing, and testing these standards to help fleets go electric. If you have more questions about VDV 261 or are ready for a compliant charging solution, get in touch.